Our Services

We offer customized, high-quality, and cost-effective solutions to help sugar mills maximize efficiency and productivity.

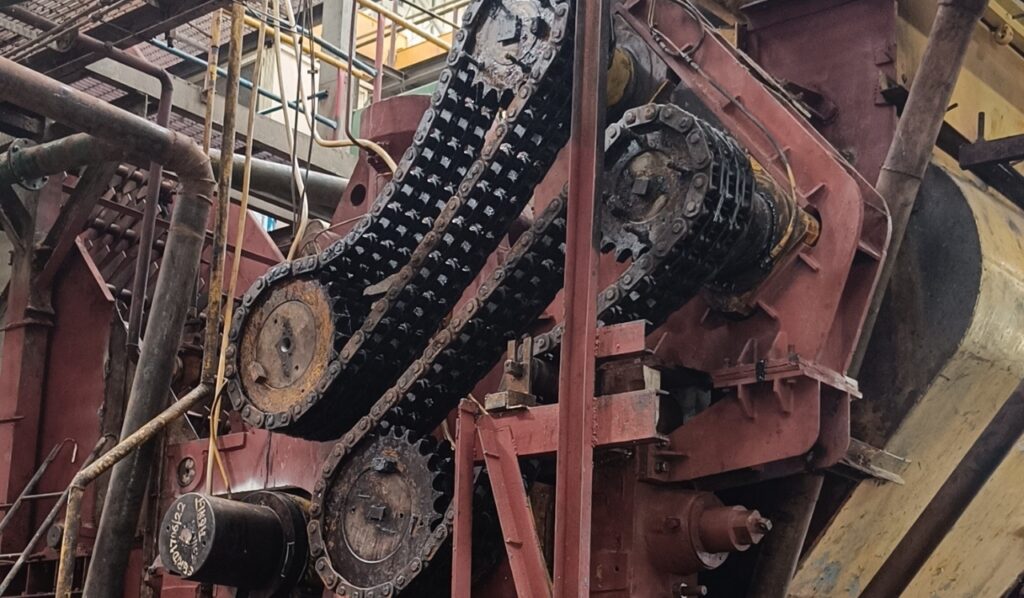

Cane Preparatory Devices.

Cane preparatory devices in a sugar factory are machines used to prepare sugarcane for efficient juice extraction. These devices include levelers, cutters, fibrizers, and shredders, which break down the cane into smaller pieces to enhance juice extraction in the milling process. Proper cane preparation increases extraction efficiency, reduces power consumption, and improves overall sugar recovery.

All Carriers.

In a sugar factory, all carriers refer to conveyor systems used for transporting sugarcane, bagasse, or other materials between different processing stages. Common types include main cane carrier, intermediate carrier, and bagasse carrier. These carriers ensure a continuous flow of materials, optimizing efficiency in the crushing and juice extraction process.

Unloaders & Feeder Table.

Unloaders & Feeder Table are essential components in a sugar factory for handling and preparing sugarcane before processing.

Unloaders: These are mechanical systems, such as crane unloaders or grab unloaders, used to lift and transfer sugarcane from trucks or tractors to the feeder table.

Feeder Table: It is a conveyor-type table that receives the unloaded cane and evenly feeds it into the cane carrier for further processing.

These systems help in maintaining a steady flow of sugarcane, ensuring efficient milling operations.

Sugar Mills.

Sugar Mills are the primary processing units in a sugar factory where sugarcane juice is extracted. They consist of a series of heavy-duty rollers that crush prepared sugarcane to extract the maximum amount of juice. The extracted juice is then processed to produce sugar, while the leftover fiber, called bagasse, is used as fuel. Efficient milling improves juice recovery, reduces losses, and enhances overall production efficiency.

Boiling House Equipments.

Boiling House Equipment in a sugar factory is used for processing sugarcane juice into crystallized sugar. Key equipment includes:

Juice Heaters – Heat the extracted juice for clarification.

Clarifiers – Remove impurities from the juice.

Evaporators – Concentrate the juice by removing excess water.

Crystallizers – Facilitate sugar crystal formation.

Centrifugals – Separate sugar crystals from molasses.

These equipment ensure efficient sugar production with high purity and recovery rates.

Old Sugar Plant Machinery Installation.

Old Sugar Plant Machinery Installation involves the relocation, refurbishment, and setup of used sugar factory equipment to restore its operational efficiency. The process includes:

Inspection & Refurbishment – Assessing and repairing worn-out components.

Dismantling & Transportation – Carefully removing machinery and transporting it to the new site.

Reinstallation & Alignment – Properly positioning and aligning mills, boilers, centrifugals, and other equipment.

Testing & Commissioning – Ensuring smooth operation before full-scale production.

This process helps in cost-effective expansion or modernization of sugar production facilities.

Sugar Mill Consultant.

A Sugar Mill Consultant provides expert guidance on the design, setup, operation, and optimization of sugar mills. Their services include:

Project Planning & Feasibility Studies – Assessing the viability of new or upgraded sugar mills.

Machinery Selection & Installation – Advising on the best equipment for efficient production.

Process Optimization – Enhancing extraction, boiling, and crystallization efficiency.

Energy & Cost Management – Reducing operational costs and improving energy efficiency.

Troubleshooting & Training – Resolving technical issues and training staff for better performance.

Consultants help improve production efficiency, reduce losses, and maximize profitability in sugar mills.

Import And Export Consultant

An Import and Export Consultant provides expertise in international trade, helping businesses navigate regulations, logistics, and market strategies. Their services include:

Trade Compliance & Documentation – Ensuring adherence to customs regulations, tariffs, and legal requirements.

Market Research & Strategy – Identifying profitable markets and sourcing opportunities.

Logistics & Supply Chain Management – Optimizing shipping, warehousing, and distribution.

Customs Clearance & Duty Optimization – Managing paperwork, reducing duties, and handling trade barriers.

Risk Management & Financial Advisory – Mitigating risks related to currency exchange, contracts, and trade policies.

FAQ

What services does Atharva Creative Technology (ACT) provide?

We specialize in designing, manufacturing, installing, and consulting for sugar plant equipment. Our services include cane preparatory devices, carriers, cane unloaders, feeder tables, sugar mills, boiling house equipment, old sugar plant machinery installation, and sugar mill consultancy. We also offer plant, machinery, and equipment valuation services.

Can ACT assist with the installation of old sugar plant machinery?

Absolutely! We specialize in relocating, refurbishing, and installing pre-used sugar mill equipment. Our process includes dismantling, transportation, reassembly, and performance optimization to ensure smooth operation.

Do you offer valuation services for sugar mill equipment?

Yes, ACT Engineers provides multi-asset class valuation services for sugar plants, industrial equipment, and machinery. Our valuation reports are widely accepted by banks, insurance companies, and private clients across India.

Do you provide customized sugar mill equipment?

Yes, we offer customized equipment and machinery tailored to meet the specific requirements of our clients. Our team of experienced engineers and technologists ensures that the solutions are efficient, cost-effective, and reliable.

What industries do you serve?

While our primary focus is on sugar mills, we also cater to industrial and process plants, construction equipment, and other complex engineering assets requiring expert valuation and consultancy services.

Why should we choose ACT for our sugar mill needs?

With 15+ years of experience, a strong focus on quality and innovation, and a team of skilled professionals, ACT provides end-to-end solutions for sugar mills. Our commitment to efficiency, cost-effectiveness, and customer satisfaction makes us a trusted partner in the industry.

© 2025 All Rights Reserved.